We must buy the water we drink;![]() our wood can be had only at a price.

our wood can be had only at a price.

Remind anyone of what people do in America today?

Chicken Plucking Report

This morning I took the plucker over to some friend’s house and helped butcher their 30 some odd Cornish Cross birds. I got there just before seven a.m. and then set up (including screwing the cones to the stand thingy) and we were done (including clean up and putting all of the stuff back into the truck) by 11:45 a.m. The plucker worked beautifully. The vote was unanimous that it saved many, many hours in the plucking department. The last time they did chickens they borrowed a table style plucker–it made a real mess and didn’t really do a very good job. The birds were plucked once on the machine, two or three times by the eviscerators (sp?) once in the house–where they cut them up and packaged them-–and then once before you put them in the pot to cook! With the Whizbang method the machine plucked them once and then the people pulled out a few tail feathers and that was it! It took me a few times to get the scalding down, but once I “mastered” (really I’m no where close) that it was a breeze.

Well I’ve been getting up at five or six for the past week or so and not going to sleep unitl midnight so I’m kinda tired (slept for two hours on the couch and still feel like I could sleep for a week) so that’s it for now.

Matthew

A Completed Chicken Plucker and a few Other Thoughts

It’s quite chilly this morning. We open the windows last night because it’s supposed to get up close to 80 degrees today but as I sit here at the computer my fingers are so cold (and slightly numb) that I’m having a hard time typing. Yesterday I could see my breath in the morning. I’ve had to dig out the flannel shirts and sweat shirts again. (‘Course if it was winter I’d be wearing a short sleeved t-shirt–it’s only getting down in the low fifty’s or high forty’s!)

The Amazing and Famous Plucker Project

Well I finally finished it. It’s been a kinda long process, I started gathering parts in February, but I took a few breaks too (some longer than others!) –to help some friends with lambing, to wait for more parts to come and to work on other things. However The Whizbang Tub-Style Mechanical Chicken Plucker is now complete and ready to try out (I even added a couple of up-grades–one was in the plan book and one I came up with my self.) And so without further ado…(drum roll please)…here’s a picture:

As y’all can see, it’s quite nice, if I do say so myself! You can also see that I added the “Mobile Whizbang” option. Here it is in action:

That blue plastic tub was just the right size to cover up the motor (which must weigh about 50 lb!) This is a sideways picture of the bottom pulley’s etc. Right now I have the wrong idler pulley on there-it’s a v-grove and I need to replace it with a flat one, but it works….

And now for my own innovation…..see if ya can guess what it is from this picture:

Here’s another clue….

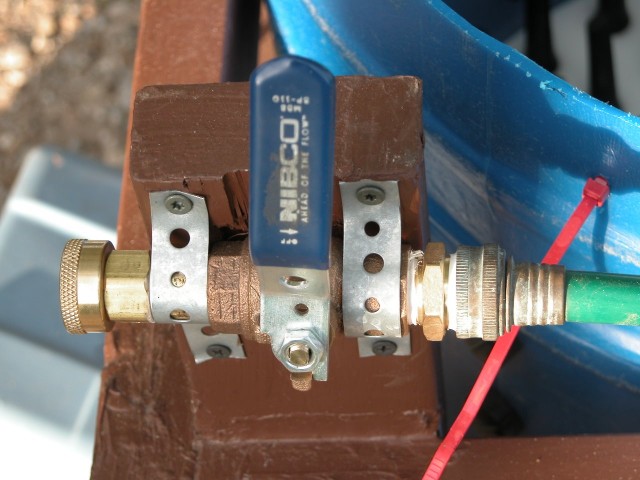

What you are looking at is….A rigged up spray ring (so ya don’t have to stand there with the hose for the ten or fifteen seconds it takes to pluck a couple of birds–just flip the lever! Who has time to stand around and wait for ten whole seconds!?! ;-) )

What I did is took an old hose (hard rubbery plasticy stuff) and hooked to the 1/2″ ball valve. Then I mounted the ball valve to the plucker frame with plumber’s strap, and the hose to the plucker tub with the ever handy zip ties. Finally, I cut little one inch slits in the hose so that is sprays like this:

And then when you flip the power switch as I’m doing in the above picture…

I think that the thing might take a few feathers off! I can hardly wait till the broilers are ready now:

There they are in the Joel Salatin style chicken tractor. It has three doors–two on the front and one big one on the back which is covered with a PVC roofing material. The pen is fairly light–without the doors on I can stand in the middle and pick it right up and carry it. On the ground though, it drags a lot because of the width (digs into the ground)…so I cobbled up a dolly for it:

It’s made out of an old push lawn mower and a couple of boards. Make it do or do with out! I basically just took the handle and bolted the wheels to it. (that did end up needing some reinforcing to keep the wheel straight–weld a piece of pipe between ’em) Then I took that pesky kill switch handle thingy, and used it to hold the board at the proper angle.

I’ve also been working on some butchering tables and such (with a lot of help from the gentleman from church that gives me lumbar). I think that it’s safe to say that I’m the only one in the county with furniture grade butchering tables! This one holds two (out of three) pieces of slate counter top that another friend gave me. It’s about six feet long. Made out of planned ash boards. [He doesn’t do plugging and touch sanding though… :(

Here’s a few other things:

That would be the Whizbang Garden cart pieces in the bushes, and the two height (sitting or standing) single stand, and the fully adjustable killing cone stand. (plus a few odds and ends!) Here’s a close up of the singe stand:

And in these two you can see how the cone stand adjustment works:

The guy helping me does very poor work as you can see! (insert extreme sarcasm into that last sentence if ya haven’t already) He doesn’t have any tools either. For instance the back of the single stand are held together in part by two biscuits (wooden kind–ya wouldn’t want to eat ’em!) which were cut out with a nifty little biscuit cutter outer jobber thing. I’m very pleased with how the stuff turned out.

He also has an old cast iron double sink with drain board that he is going to give me. (Did I mention that he’s pretty generous?) Then I’ll just need to figure out how to rig up the foot operated water switch….

Well I’m out of time this morning. I get to go help worm sheep today :-)

Until next time,

May He who is able to keep you from falling make your way straight, and rescue you from all ungodliness.

Matthew

Recent Comments